Laboratory

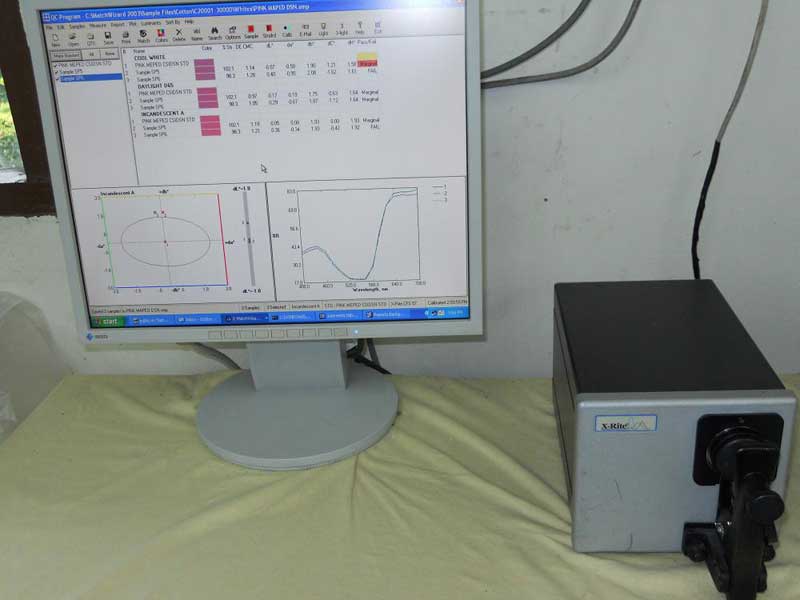

About our Lab

- The lab is equiped with up to date laboratory equipments for color matching and quality testing.

- For getting the color matched with swatch in different materials, we put a lot of effort in trial color matching, conducting physical test like light fastness, washing fastness test to select the right recipes for various customers requirements.

We use color spectrometer to assist lab color matching and color approval for world customers e.g. FOL, Mizuno etc…

Dyed Yarn

About our Dyed Yarn

- The plant has a daily capacity of 1500 kgs to 2000kgs

- Latest technology coupled with technical expertise are available to achieve consistency and efficiency.

- Selected dyestuffs and chemicals are prerequisite to maintain high quality products.

Knitting

About our Knitting

- There are 30 units of machines to knit various type of fabrics with a total daily capacity of about 10,000kgs

- Sample swatches of various design, color and density are available to meet customers’ choice.

- Garment assorries such as collars and cuffs are knitted at the plant to accommodate our integrated industry.

- Fabrics for garment production samples are also made available upon request.

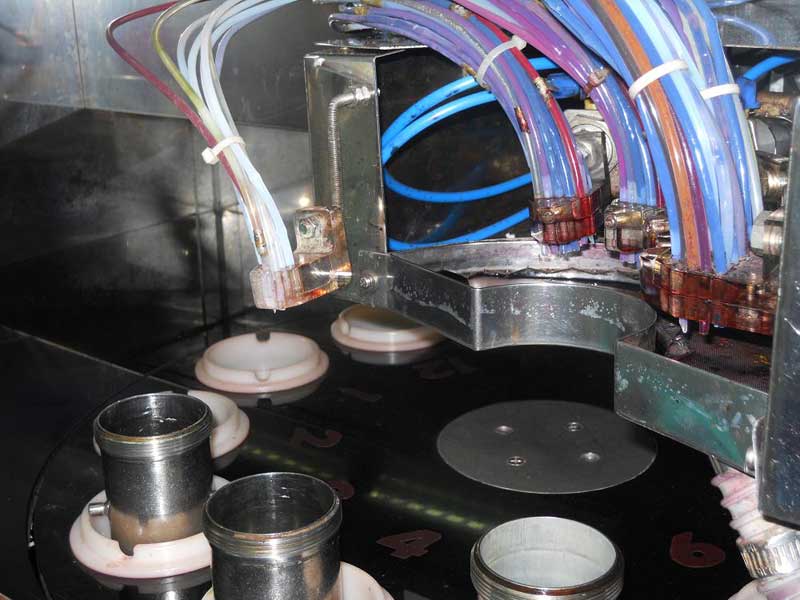

Fabric Dyeing & Finishing

About our Fabric Dyeing & Finishing

- Equiped with 30 units high pressure dyeing machines, Santex dryer and Babcock Finishing suitable to manufacture elastic fabrics with daily capacity 10,000kgs per day.

- Always available to carter customers’ requirement with accrediated lab test as approval.

- Always keep alert to new products and fashion.

Garments

About our garments

- Garment division is lead by a well experienced management team with focus on design, product quality and cost effectiveness.

- The 5-storey building plant is equipped with ERP system and up to date sewing machines to maintain its efficiency and effectiveness. Every process caters for customers’ satisfaction.